Unload blocks on a dry level surface raised above ground and cover them to prevent exposure to rain or severe weather conditions.

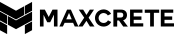

The ideal mortar mix ratio of cement and sand is 1: 4.

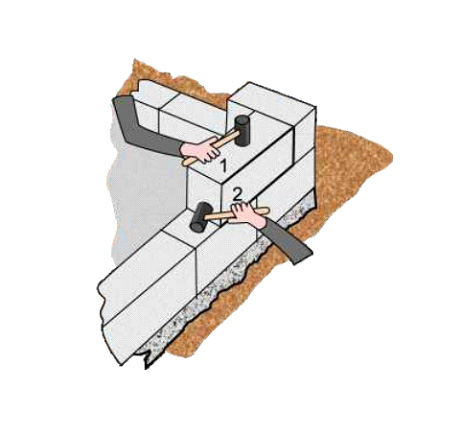

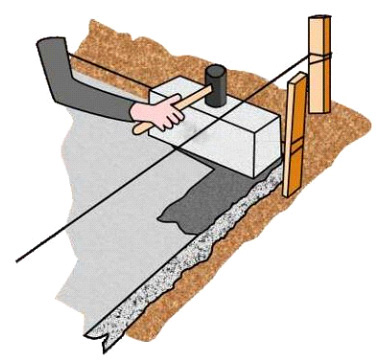

Mortar joint thickness should be 8-12 mm.

No need of Curing except for mortar joint

Plastering thickness should be 10 mm for internal walls and external plaster should be 12-15mm.

For AAC blocks, it is recommended to provision bond beams after every 1.5-2 meter with reinforcement. RCC Bond beam of thickness 75 mm with two nos of 8 mm dia. rods and 6mm stirrups at 200 mm c/c.

Maxcrete AAC blocks can be easily cut, nailed, drilled, grooved by using ordinary hand tools.

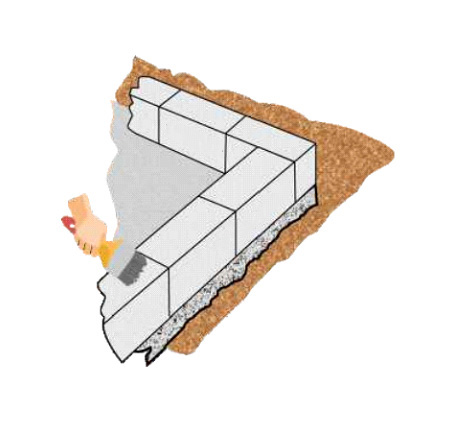

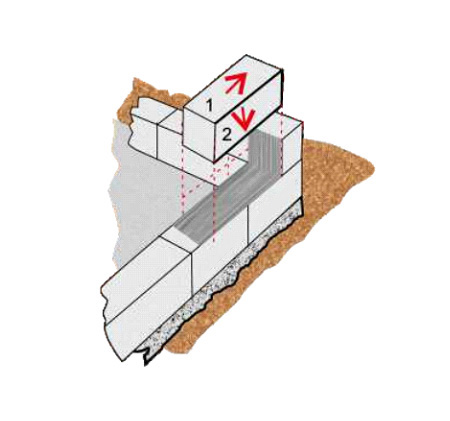

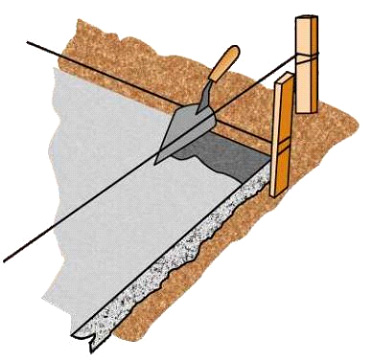

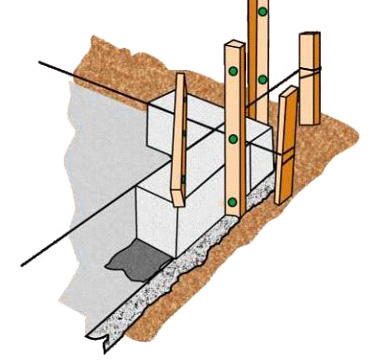

1st Level Coursing:

Normal Course: